The latest in production management technology

KANSAS CITY, MO. - Wynne Barrett has intimate first-person knowledge about the coronavirus.

Barrett, a partner in Hopkinton, Massachusetts-based software specialist Jera Concepts, first took care of his wife in their Connecticut home after she came down with the virus. After a few days, she was mostly back to normal.

Barrett also contracted the virus, but he wasn’t so lucky. He had a fever for 16 straight days. Fortunately, he didn’t have any other symptoms, and he was usually able to do at least some work each day.

As a company, Jera has been comparatively lucky. Other than a small support staff in the company’s Hopkinton headquarters, everyone else works from their own offices anyway. Jera didn’t have to lay anyone off.

But of course that doesn’t mean the company hasn’t been affected like everyone else. The company cut prices for some of its clients who were suffering severe economic fallout from the pandemic.

“We know they’re hurting, so we should hurt a little bit, too,” Barrett said. “Everyone’s down 40 to 60%, though the grocery piece is still hanging in there.”

Fortunately for Jera and its customers, the production management software the company provides can really prove its value in difficult times like this, Barrett said.

Some of the biggest challenges the manufacturers Jera works with have had during the outbreak is staffing. One result of that has been split production schedules, where two production cycles are run with the same, smaller group of employees working longer hours — instead of one group of people handling one cycle and another the second.

Menu simplification has been another effect of the coronavirus, Barrett said. If a food producer only has 10 people coming into work, they may make only half of the products they usually make.

“For us, mostly we’re just trying to help them change orders quickly,” he said. “You go down (in production), but then you go down too much. The tools we have help groups with that. They’re able to pull products, make percentage drops in ordering, have a whole suite of software with the ability to help them change things.”

On the issue of split production, Jera’s software allows companies to separate production into components, rather than one just have “one big production,” he said.

A new model, post-virus

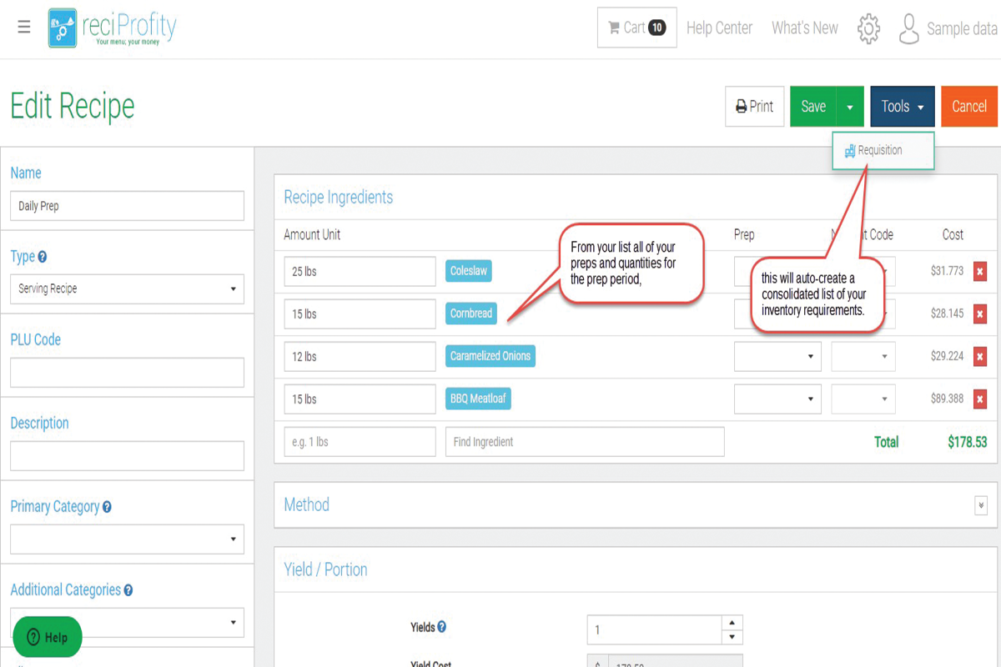

Bronxville, New York-based At-Your-Service Software Inc., makers of cloud-based ReciProfity food costing software, has seen increased competition for take-out foods because of the coronavirus. As a result, retailers have to be even more creative and cost-conscious, said Matthew Starobin, the company’s CEO.

“On the costing side, we see lots of user data that does not include packaging as a food cost. Since packaging is a direct recipe (as opposed to overhead and labor), we think it belongs in the recipe, and accounted for in the selling price,” he said. “I think that the delivery will embedded in the restaurant model forever, and won’t recede when the virus is behind us.”

The “retail vigilance” Starobin describes must therefore be followed going forward. Decisions related to IT, apps, etc. must be informed by these new rules.

One thing, however, that hasn’t changed with the coronavirus, Starobin said, is the need to “produce to par.” A production system should be able to tell operators exactly what’s needed, so prep people pull only the required inventory.

“Operators tell us that production waste is a huge variable cost that requires controls and oversight. Since we have so many grocery users, ‘produce to par’ is an essential feature.”

At-Your-Service has seen retailers more and more concerned with production costs, i.e. “really managing the waste potential in daily prep,” Starobin said.

With ReciProfity, that task is much easier.

“Kitchen prep can now view and scale recipes on a tablet right in the kitchen, and see the required quantities without leaving their station,” Starobin said. “That’s a major improvement over having to go to a desktop PC, scale, then print the recipe. And prep people never underestimate, so invariably there’s waste. The other maybe more serious repercussion is that recipes then deviate from standards.”

At-Your-Service provides customized versions of ReciProfity for retail chains large and small. Some customizations, for example, can allow companies to verify labels, nutritionals, allergens, ingredient declarations and other information.

The company’s software can be especially helpful for purveyors of prepared foods, a category that can be especially difficult to monitor because ingredients needs to be sorted by weight, Starobin said. That can’t be done effectively without a high-end software solution.

New for 2020

New in June, Jera is rolling out a new iteration of its “What to make when” suite of software to help retail clients with production management. The tools are particularly important for prepared foods sections that sell hot-holding items (e.g. rotisserie chickens), where knowing how much product to have at the right times is critical.

“We’re so excited about it,” Barrett said of the updated package. “Taking the sales feed in the hot grab-and-go category, you’ll have the ability in real time to view what you need to be making to satisfy upcoming business needs — whether it’s by the hour, shelf life, 30 minutes, whatever.”

“What to make men” is mainly designed for hot prepared foods, but it’s also good for cold grab-and-go, Barrett said.

Slowly but surely, he added, grocery chains are coming around to the idea of becoming more tech-savvy when it comes to production management and deli prepared. The days of relying on Excel alone are starting to fade.

The main issues are theoretical use vs. actual use and consistency, Barrett said. When prepared foods are made inhouse, it can be hard to ensure consistency of product from one store in the chain to the next.

Also new for Jera, the company now offers it customers software that connects with Web-enabled label printers that helps address problems related to implied waste — the gap between what sales should have been for the day, and what sales actually were.

“It’s able to create a forecast, then you get a feed of exactly what was made, then you compare to what sales were for the day,” Barrett said. “It lessens need for accurate employee waste recording, which is always bad — people are not good at entering, regardless of waste.”

Forecasting technology has seen significant improvements in recent years, led by Amazon, Barrett said.

“As those engines get more sophisticated, it will be simpler to factor in crises like pandemics, hurricanes. Every few years we have a lot groups in Florida where a hurricane wreaks havoc. Technology is advancing, forecasting is improving, which makes it easier.”

This story appeared in the June 2020 issue of Supermarket Perimeter. Check out the full June magazine here.